New digital opportunities ("internet of things", "cloud computing", "big data" ...), the development of circular economy, the reorganization of production means, recycling and re-production, and the growing demand for sustainable development are inevitably transforming products and production systems and questioning the way future products and systems should be designed. With an approach based on integrating design on manufacturing in order to boost environmental performance, the CPP team develops models and offers design methods and organizations in line with emerging technologies leading to new forms of consumption and production.

The team's projects are shaped around our two main research areas:

CPP Home

The team's projects are shaped around our two main research areas:

- Design and environmental performance.

- Recycling of rare materials: Potential environmental impacts and benefits

- Design of products, processes, organizations and their life cycle (life cycle engineering)

- Development of environmental data management in relation to data product.

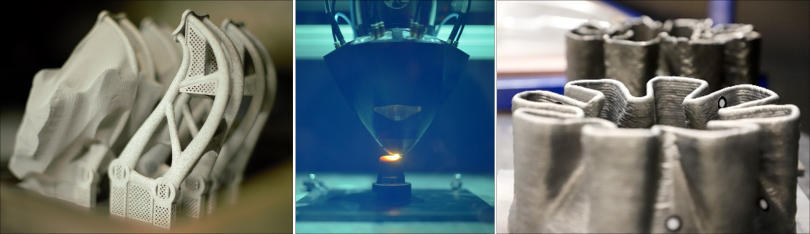

- Design / Manufacturing integration.

- Representation of manufacturing process knowledge including innovative manufacturing (additive manufacturing)

- Integration of manufacturing process efficiency in product design (energy and environment)

- Industrial management of innovation and tools for desiminating knowledge.

Scientific Challenges:

- Coordination od design under resource constraints for manufacturing (rare materials) and environmental impacts

- Understanding of sustainable consumption and production

- Eco-design methods and support tools

- Model-driven design of manufacturing processes in additive manufacturing

CPP Home