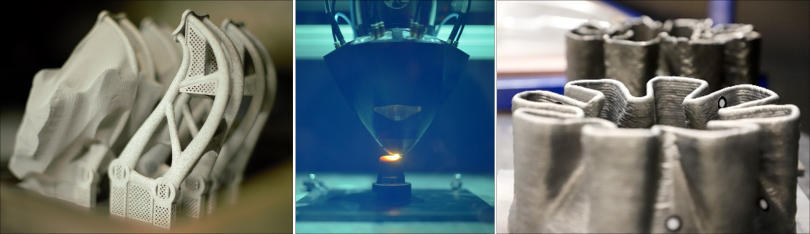

Advances in digital technology, the growth of additive manufacturing processes, and an increasing awareness of societal and environmental challenges are having a significant impact on the design and the production processes of manufactured products. Faced with these developments, the CIPP team creates models and methods based on the experience and knowledge of experts. The team thus provides tools that make it possible to master manufacturing processes and to design by integrating both technical constraints and societal and environmental needs. [find out moreEn savoir plus]

Research axes

- Design of product and process

- Methods and processes for design and production

- Knowledge formalization

- Decision support in design and manufacturing

- Phenomenological modeling

- CAD/CAE/CAM digital chain

- Quality management of part and product

Projects

- EcoDFAM - Eco-design guide for additive manufacturing (EcoSD)

- Accel 4.0 - Accelerate the company's transformation through research and skills development

- FAM - Foundry additive manufacturing (R&D Booster Regional support)

- AWESOME - Development of manufacturing strategies by hybridization of WXAM processes and 5-axis machining of complex shapes (ANR - National Agency of Research)

- CraFT - Calculation of robot trajectories for Additive Manufacturing of complex Tubes (Regional Support AURA)

- METALIC - Real-time control of trajectory and process parameters by modeling and measurement in metal additive manufacturing (ANR - National Agency of Research)

- BeShape - Design of lightweight parts manufactured by wire and arc additive manufacturing (ANR - National Agency of Research)

- FAIR - Design and manufacturing by additive manufacturing of smart products (Regional Support AURA)

- COFFA - Design and Shape Optimization for Additive Manufacturing (ANR - National Agency of Research)

- GEOCAM - Geometric control of parts produced by metal additive manufacturing (ANR - National Agency of Research)

- GreenDFAM - Eco-design for Additive Manufacturing (ANR - National Agency of Research)

- CRIFA - Non-destructive testing by photothermal radiometry of parts produced in WAAM Additive Manufacturing (Carnot ARTS and Carnot Énergies du Futur)

PhD thesis proposal

Opportunities

View PhD opportunities within the laboratoryOngoing and defended

View current and past theses of the team

Ressources

- Additive manufacturing - Powder Bed fusion E-PBF

- Additive Manufacturing - Wire Arc Additive Manufacturing WAAM

- Hybride Manufacturing MOCN - WAAM

- Additive Manufacturing - Wire Laser Additive Manufacturing WLAM

- Rapid Prototyping and Additive ManufacturingFabrication additive

- Softwares