Background

Université Grenoble-Alpes, 2015

PhD supervisor: Henri PARIS

PhD co-supervisor: Matthieu MUSEAU

Partnership: G-SCOP

Research Process

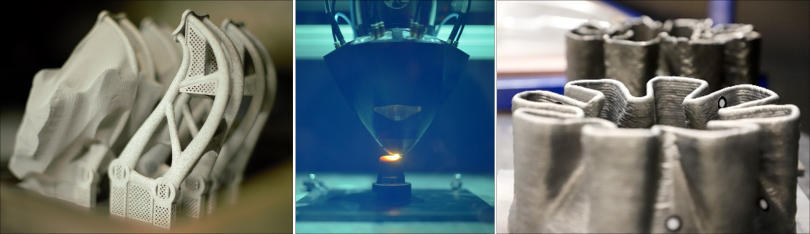

- Put in light harmful effects. Understand what affects additive manufactured part in a good way or not, and how.

- Study the impact of these parameters to particular cases. Observe and characterize the influence that can have a setting on geometry, material integrity of some part type (full, architected, trellises, etc.)

- Certification process for material integrity and / or geometry. Think about and implement a process that is able to validate the material integrity of parts and / or its geometry.

Expected Results

- Creation of a qualification tool. A tool able to validate the properties of a design and a material without necessarily testing directly the part.

- Classification of parameters and their impacts. In order to better understand and apprehend the various defaults and problems that can affect parts made by EBM

Last Updated 2016.01.13