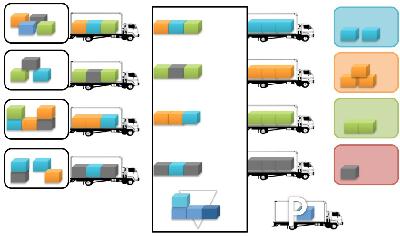

Study of supply chain problems involving production, storage, and transportation. We are particularly interested in generalizations of the lot-sizing problem.

Topic Description

Globalization of economy increases the focus of large companies on their supply chain design. How do we optimally schedule the production, storage and transport are critical issues commonly encountered by supply chain managers. These problems are often related to the academic lot-sizing problem and can be seen as extensions of the latter. The coupled lot-sizing is also at the heart of our work (coordination of several companies) since it allows a transport densification and reduces environmental impact while resulting in economic gains.

These questions also arise naturally when decisions are taken by several actors (distributed optimization). We study in this context the possible mechanisms of coordination between customers and suppliers.

Finally, we are working on issues linking the design and the life cycle of products with the supply chain. Optimization problems arise when companies rely on modular conception to offer a wide variety of offers. Finally, we try to take into account the product life cycle in the design. The supply chain management in this context leads us to consider reverse logistics for managing end life of products.

These questions also arise naturally when decisions are taken by several actors (distributed optimization). We study in this context the possible mechanisms of coordination between customers and suppliers.

Finally, we are working on issues linking the design and the life cycle of products with the supply chain. Optimization problems arise when companies rely on modular conception to offer a wide variety of offers. Finally, we try to take into account the product life cycle in the design. The supply chain management in this context leads us to consider reverse logistics for managing end life of products.

Collaborations

- Lot-sizing and distribution with Université de Batna (Algeria)

- Product and supply chain design with Ecole Polytechnique de Montreal and Université de Laval (Quebec)

- Reverse logistics with Renault and Danone Eaux France for the workflow of reusable parts as bins, bottles, good containers, etc.

- École Mahammadia d'ingénieurs de Rabat

- Université de Metz

- Université Paris VI

- École des Mines de Saint Étienne

Thèse(s) en cours

- Bertrand Baud-Lavigne, Optimization of the supply chain desig for product families with complex nomenclature

- Bertrand Hellion, Coordinating agents in a sustainable supply chain

- Laurent Lim

Contacts

Bernard Penz

+33 (0) 4 76 57 43 14

Bureau: H311

+33 (0) 4 76 57 43 14

Bureau: H311

Mots clefs

Lotsizing, Supply chain