Background

An adequate innovation management in the production enables the production to act strategically and innovatively in responding to change. This thesis is embedded in the context of a real industrial environment of the large German automotive tier-1 supplier ZF Friedrichshafen AG, which develops and produces transmissions, dampers, clutches and chassis modules. The PhD student is a part-time employee in this company as a project manager in the strategic production planning (SPP) department of the commercial vehicles transmissions division.

In numerous companies innovation management is predominantly concerned with product development in terms of structuring and managing the steps leading to innovative products and services. Innovation is thus focussed on products and services much more than on manufacturing. However, production needs to innovate as well to satisfy the diversity of internal requirements such as profitability, competitiveness, time to market, supplier relationships, etc. [1]. Industries are therefore looking for methods and tools helping them to drive product, service and process innovation also by their manufacturing technologies and are seeking to a methodological support for SPP to plan such investments systematically, reliably, and with a holistic view. Industries are looking for a systematic, measurable approach that involves all the required stakeholders [2], as well as a way to deal with the uncertainty and risk that is intrinsic to long-term SPP [1]. Technology roadmapping (TRM) is well established in industry as a strategic management tool for organizations to adapt themselves better to modern marketplaces [3]. It application to SPP, however, has not been investigated in research so far. This thesis aims at developing and establishing a TRM process for production technology innovation.

In numerous companies innovation management is predominantly concerned with product development in terms of structuring and managing the steps leading to innovative products and services. Innovation is thus focussed on products and services much more than on manufacturing. However, production needs to innovate as well to satisfy the diversity of internal requirements such as profitability, competitiveness, time to market, supplier relationships, etc. [1]. Industries are therefore looking for methods and tools helping them to drive product, service and process innovation also by their manufacturing technologies and are seeking to a methodological support for SPP to plan such investments systematically, reliably, and with a holistic view. Industries are looking for a systematic, measurable approach that involves all the required stakeholders [2], as well as a way to deal with the uncertainty and risk that is intrinsic to long-term SPP [1]. Technology roadmapping (TRM) is well established in industry as a strategic management tool for organizations to adapt themselves better to modern marketplaces [3]. It application to SPP, however, has not been investigated in research so far. This thesis aims at developing and establishing a TRM process for production technology innovation.

PhD candidate: Martina FLATSCHER

Université Grenoble-Alpes, 2013

PhD supervisor: Andreas RIEL

Partnership:

Research process

The first year of this thesis work was focused on the research to identify the state of the art of published research results covering tools used or proposed for strategic production technology planning with a particular focus directed on TRM. In order to have a systematic guidance in our literature review bibliometric analysis based on Thomson Reuter’s Web of Science (WoS) is used. CiteSpace II from Chen [4] was used as analysis tool mainly because of its powerful analysis possibilities and its compatibility to WoS data. This software creates networks that visualize patterns in research relations in the form of nodes and edges. Each node represents one research article and is linked to other bibliographically coupled articles. This means that there is an overlap in the list of references of the coupled articles. The more references articles share, the stronger these articles are coupled [5]. These articles constitute a “research front”, as they are based on similar sources. Each node’s size indicates the number of times the corresponding article has been cited according to WoS. From this analysis, research gaps shall be identified by relating the research findings to the current needs in industry from the point of view of ZF whose global production network and technology have a significant value contribution to their product business.

Moreover the first year of this thesis was focused on the identification and involvement of stakeholders and the integration of engineering department, production and purchase with the target to develop and deploy a holistic SPP process. Hereby various stakeholders from different expert fields have to be involved systematically in SPP. An appropriate ideation process and idea management regularly involving stakeholders from production, product/service development, procurement, etc. is vital for making SPP operational and effective. The output of this process would feed the strategic planning instrument, TRM in current industry practice.

The second year will deal with the specification of the process, its integrated deployment and evaluation. Finally, the third year will be dedicated to the generalization of concepts and the compilation of the thesis.

Moreover the first year of this thesis was focused on the identification and involvement of stakeholders and the integration of engineering department, production and purchase with the target to develop and deploy a holistic SPP process. Hereby various stakeholders from different expert fields have to be involved systematically in SPP. An appropriate ideation process and idea management regularly involving stakeholders from production, product/service development, procurement, etc. is vital for making SPP operational and effective. The output of this process would feed the strategic planning instrument, TRM in current industry practice.

The second year will deal with the specification of the process, its integrated deployment and evaluation. Finally, the third year will be dedicated to the generalization of concepts and the compilation of the thesis.

Expected results

A systematic approach to planning investments in and deployment of modern manufacturing technologies in a way that industrial organizations get an actionable guidance to deploying production technology planning successfully.

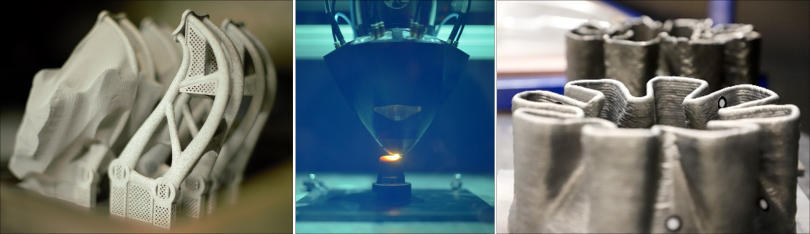

Figure 1. Strategic production planning for innovation management

[1] Brettel, M., Bendig, D., Keller, M., Friederichsen, N., Rosenberg, M., 2014, Effectuation in manufacturing: how entrepreneurial decision-making techniques can be used to deal with uncertainty in manufacturing, Procedia CIRP 17:611-616.

[2] Flatscher, M., Riel A., Kösler, T., 2014, The Need for a Structured Approach towards Technology Roadmaps in Innovation-driven Industries, Systems, Software and Services Process Improvement, Springer CCIS, 425:251-261.

[3] Phaal, R., Farrukh, C.J.P., Probert, D.R., 2004, Technology roadmapping – A planning framework for evolution and revolution, Technological Forecasting & Social Change, 71:5–26.

[4] Chen, C., 2006, CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature, Journal of the American Society for Information Science & Technology, Vol. 57/3:359–377.

[5] Kessler, M.M., 1963, Bibliographic Coupling Between Scientific Papers, American Documentation, 14/1:10–25.

Last Update 2015.02.20